3D Printing and 3D Modeling services

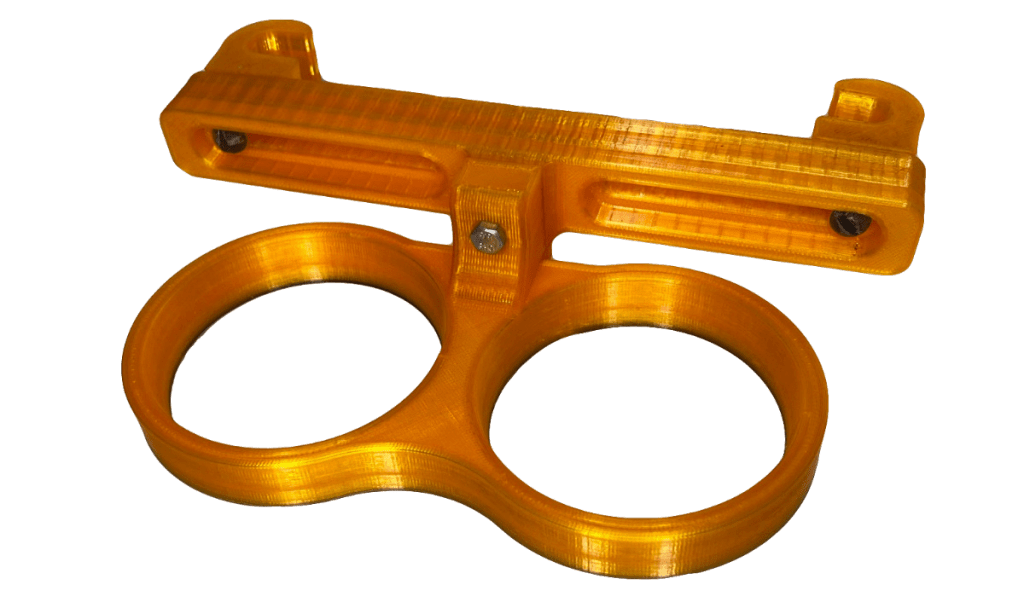

The 3D printing process allows you to create objects from your imagination or multiply them quickly and easily.

We print anything for you

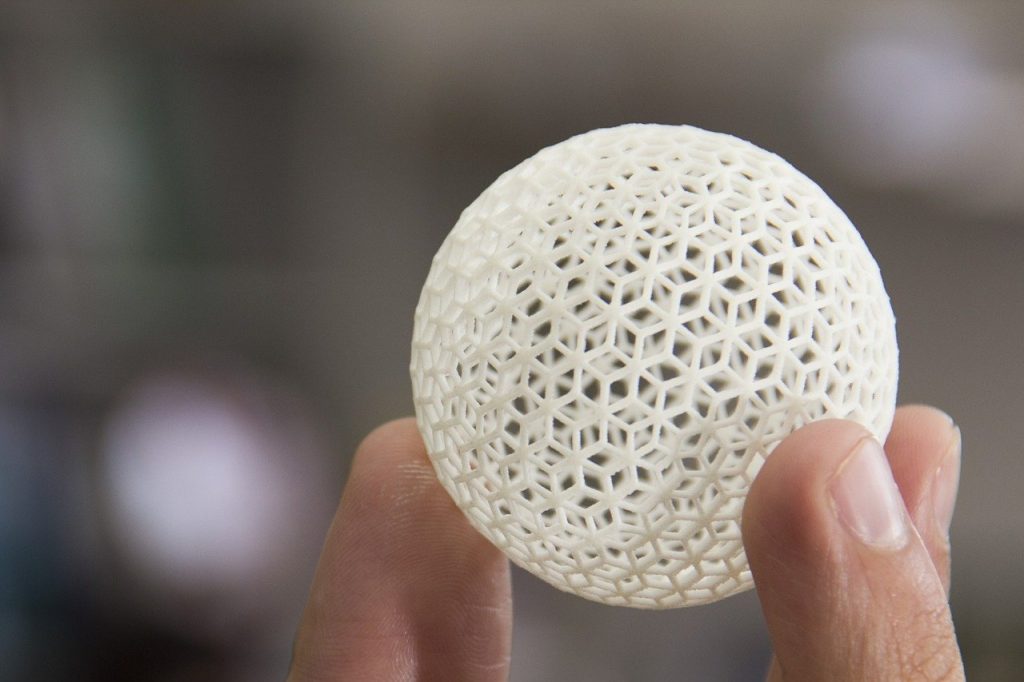

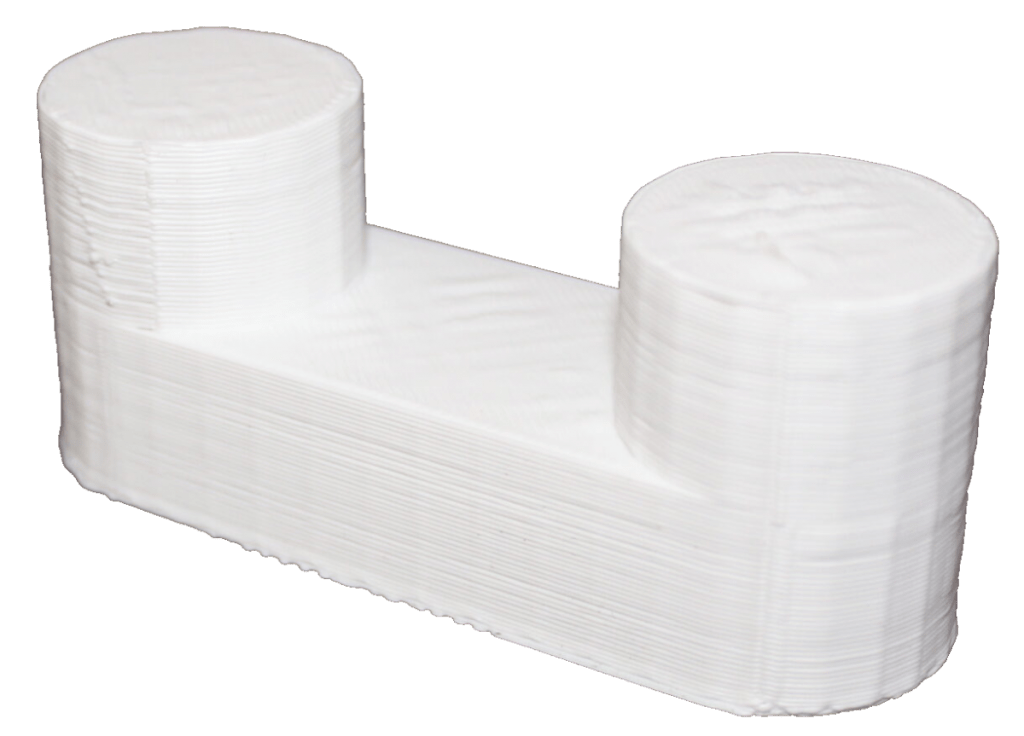

Although it seems a simple process, behind this technology, are many elements that contribute to getting the final result. The printer overlaps several very thin layers of material, giving it the shape of a digital model. Objects made with 3D printing techniques can be changed in different ways. Regardless of the project, you are using, we will find the best solutions. Our customers’ ideas can be turned into reality. The quality of the products is ensured by the latest generation 3D printer. However, we are in a continuous process of learning and improvement. We adapt to the latest trends in the industry to offer you high-quality products and services.

Even if you do not have 3D modeling skills, but you want to create some objects, we provide you with the 3D modeling service. Therefore, it represents the process of creating three-dimensional objects, respectively models that are used in graphic simulations, commercials, video games, etc. Our 3D printing service guarantees that it can bring to life any element you have thought of.

3D printing services are the perfect solution for unique, personalized, or out-of-store products. Our team will turn your idea into a digitized reality. We will make sure that the product will look exactly as you imagined. We will successfully meet all your requirements down to the smallest detail.

Available materials

Polylactic acid – PLA

Use in 3D printing

Used for prototypes that require a superior finish and medium mechanical strength.

Limitations in 3D printing

Not suitable for products subjected to mechanical stress or high temperatures.

Features for 3D printing

Impact resistance: 7.5kJ / mp (ISO180 / A)

Tensile strength: 110MPa (MD) (ASTM D882)

Modulus of elasticity: 3310 MPa (MD) (ASTM D882)

Elongation at break: 160% (MD)

Bending modulus of elasticity: ± 2392.5 MPa

Hardness: –

Acrylonitrile butadiene styrene – ABS

Use in 3D printing

Used for prototypes that require good mechanical and chemical resistance

Limitations in 3D printing

It is quite difficult to print due to the appearance of deformations during printing as well as the frequent detachment of the platform.

Features in 3D printing

Impact resistance: 36kJ / mp (ISO180 / A)

Tensile strength: 38MPa (ISO527)

Modulus of elasticity: 1900 MPa (ISO527)

Elongation at break: 9% (ISO527)

Bending modulus of elasticity: ± 2250MPa

Hardness: 74MPa (ISO2039-1)

Polyethylene terephthalate glycol – PETG

Use in 3D printing

Used for prototypes that require good impact resistance and good thermal resistance.

Limitations in 3D printing

Limited possibilities of bridging, thin spider-like threads may appear on the surface of the print due to the characteristics of the filament.

Features for 3D printing

Impact resistance: 7.2kJ / mp (ASTM D256)

Tensile strength: 50MPa (ASTM D638)

Modulus of elasticity: 1940 MPa (ISO527)

Elongation at break: 120% (ASTM D638)

Bending modulus of elasticity: ± 2147.6 MPa (ASTM D790)

Hardness: 105MPa (ASTM D785)

Synthetic resin

Use in 3D printing

Used for prototypes that do not require very good mechanical strength, a chemical resistance similar to ABS, but a superior finish that cannot be obtained by FDM printing.

Limitations in 3D printing

Long print times, small model size

Features for 3D printing

Modulus of elasticity: 3730 MPa (ISO 527)

Flow resistance: 74.4 MPa (ISO 527)

Flow elongation: 2.5% (ISO 527)

Young’s mode: 12 kJ / sqm (ISO 179-2)

HDT A: 74 ° C (ISO 75)

HDT B: 121 ° C (ISO 75)

Density: 1.18 g / cm3 (ISO 1183)