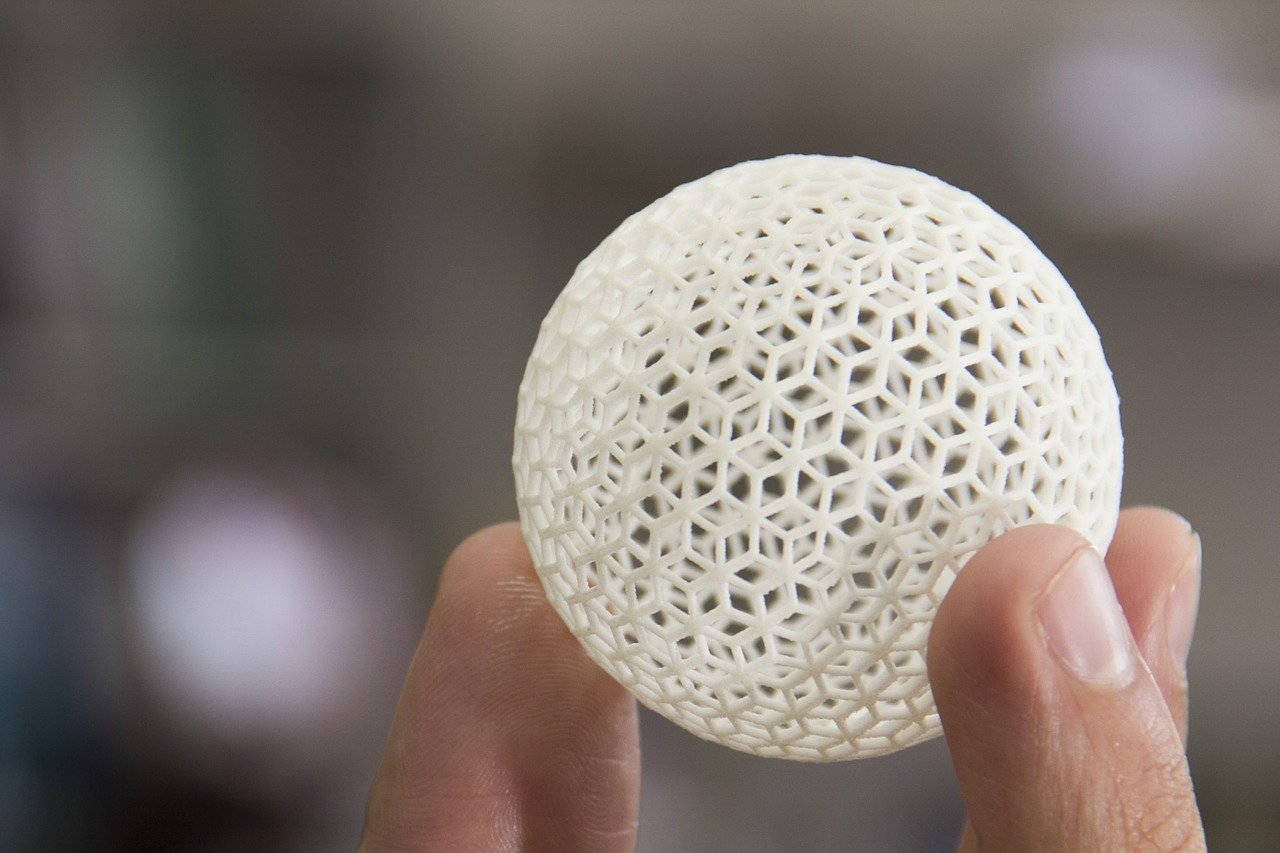

Due to the competition in the field of product manufacturing, a series of innovative processes for making 3D models have emerged. 3D printing is part of the category of innovative manufacturing processes with huge development possibilities for a wide range of applications.

For a better understanding, we will further present the 3d printing advantages.

Cost reduction

3D printing can bring cost efficiencies to machining on numerically controlled machines, such as energy costs, raw material costs, and personnel costs.

Design optimization

Product optimizations are required for certain industrial applications in terms of product weight or dimensions. With the help of the 3D printing process, prototypes of the 3D models can be made, thus allowing their possible modifications.

Possibility of customization

3D printed products can be used by different customers, so 3D printed models must be easily customizable to meet the needs of each customer.

Decreased production time

Compared to traditional production variants, by 3D printing, we can turn a 3D model into reality in just a few hours. There are also large 3D models that require a long time, but for small or single series production, 3D printing is definitely a reliable solution.

Reuse of materials

The 3D printing process seeks to apply the principle of sustainability, by using environmentally friendly materials and by reusing materials for future 3D printed products.